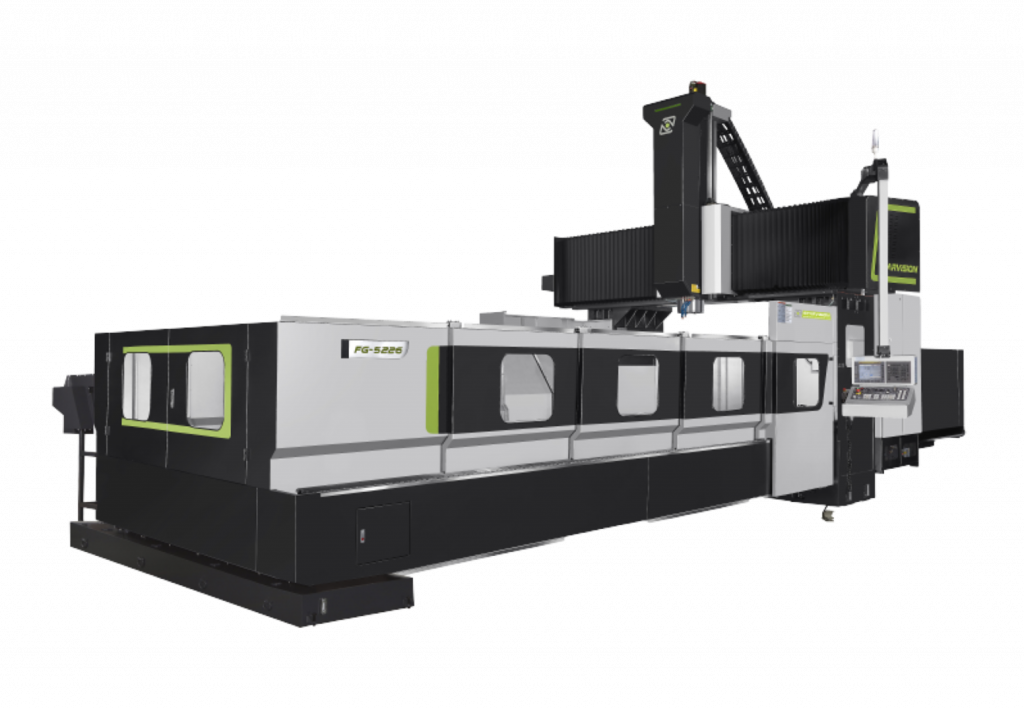

Stable in precision and flexible in length. The FG series is an extension of the LG series. The

base is equipped with three sets of R55 linear guides, a wider working table and an extended

X-stroke up to 10.200 mm. The aim is to offer the customer an alternative for medium to

large processing sizes.

| Features | Unit | FG-6226 |

| Stroke (XYZ) | mm | 6.200 x 2.600 x 1.000 (1.200 – op) |

| Distance spindle nose to table | mm | 150-1.150 (150-1.350 – op) |

| Dimensions of the working area | mm | 6.000 x 2.400 |

| Max. workpiece weight | kg | 19.000 |

| Motor power | KW | 18.5 / 22 (22/26 – op) |

| Max. spindle speed | rpm | 6.000 (8.000 – op) |

| Spindle taper | – | BT50 / ISO-50 / CAT50 |

| Quick stroke X/Y/Z | M / min | 8 / 15 / 12 |

| Max. number of tools | kom | 32 (24/40/60/90 – op) |

| Max. tool diameter | mm / inch | ∅125 |

| Max. tool diameter without adjacent tool | mm / inch | ∅245 |

| Max. tool length | mm | 350 |

| Max. tool weight | kg | 20 |

| Controller | FANUC 0i-MF | ST |

| FANUC 31i-MB | OP | |

| MITSUBISHI M80 / M830 | OP | |

| SIEMENS 828 / 840D | OP | |

| HEIDENHAIN | OP | |

| Spindle | 18.5/22 kW spindle motor | ST |

| 22/26 kW spindle motor | OP | |

| 8,000 rpm with reduction gear | OP | |

| 6,000 rpm with reduction gear | ST | |

| 8,000/10,000 rpm with a direct drive | OP | |

| Automatic tool changer | 32 tools | ST |

| 40/60/90/120 tools | OP | |

| Mechanical | Automatic lubrication system | ST |

| Spindle cooling | ST | |

| Blowing through the spindle | ST | |

| Manual encoder | ST | |

| Working light | ST | |

| 3-colour warning light | ST | |

| Cooler on the door of the electrical cabinet | ST | |

| Air and water gun | ST | |

| Double screw system for removing chips | ST | |

| Chip conveyor with waste box | ST | |

| Cooling through the spindle 20/40/70 bar | OP | |

| Transformer | OP | |

| Oil skimmer | OP | |

| Oil mist air cleaner | OP | |

| Other | CE certificate | OP |

| CNC rotary table | OP | |

| Measurement options |

Heidenhain measuring scales | OP |

| Measuring of tools | OP | |

| Determination of zero points | OP | |

| 4th axis | Preparation for 4th axis | OP |